Auxiliary equipment

NEAEN DiMix dissolver for marinades, brines, and syrups

Designed for preparing high-quality marinades, brines with crystal salt, as well as various syrups with the addition of flavor enhancers and essences in small quantities. Perfectly suitable for dissolving pectin and other thickeners, as well as similar products. marinades brines dissolving thickeners syrups other similar products Design The plant comprises two operating tanks. The first…Read More

Enigma colloid mill

This is an ideal solution for continuous grinding of particles in suspensions, as well as viscous, semi-hard and hard products, without preliminary grinding (e.g. nuts). Options: ATEX-compliant version Various steel grades Frequency adapter for changing rotor speed Cooled stator Adjustable feed device Level indicator in feed funnel Recirculation and discharge device Design Enigma colloid mills…Read More

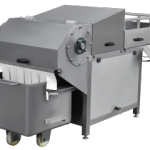

ProfiFlaker frozen blocks flaker

The ProfiFlaker frozen blocks flaker is intended for flaking of frozen blocks of meat, fish and poultry (including with bones), as well as frozen blocks of juice, butter, margarine and similar products coming directly from cold storage and without prior defrosting. It includes a system to pneumatically supply blocks with reinforced guide rails on linear…Read More

Vacuum diffuser (vacuum liquid coater) NEAEN DifuVac

Vacuum diffusion is a process where the air inside of a product is eliminated with the help of a vacuum. The emptied pores are then filled with flavoring agents, vitamin additives, etc. The NEAEN DifuVac vacuum diffuser is intended for performing diffusion treatment of a wide range of products, both low- and high-density. Products: Animal…Read More

NEAEN NoCavity vibratory packer

The NEAEN NoCavity vibratory packer is used in filling lines for viscous, foamy, and difficult to dose food and non-food products. This vibratory packer ensures that containers are uniformly filled with viscous products without allowing any air pockets to form, which might lead to spoilage. The NoCavity vibratory packer guarantees that each package of your…Read More

NEAEN FC feeding conveyor

The NEAEN FC feeding conveyor consists of a hopper, the size of which is determined by the product and the necessary output, and an inclined transporter, which ensures that the product is lifted and evenly transported to a place for further processing. The volume of the hopper, the width of the conveyor, the angle of…Read More

NEAEN VF vibratory feeder

NEAEN VF vibratory feed chute is intended for even feeding and distribution of a uniform layer of product on a conveyor belt for continuous cooking or frying equipment. The width of the vibratory feeder is determined by the width of the conveyor belt that you want to pour the product on. The output of the…Read More

NEAEN OMF oil mist filtration system

NEAEN OMF innovative air-cleaning technology can significantly reduce your operational expenses for air-cleaning, raise the level of hygiene of the production area, and it ensures safety and effective air-cleaning. Advantages: Highly effective cleaning. The NEAEN OMF oil mist filtration system ensures a significant improvement in hygiene indicators in your working area and a higher level…Read More

NEAEN LCC conveyor for closing the lids on tubs and buckets

NEAEN LCC conveyors are intended for closing lids over tubs or buckets of prepackaged food products (horeca packaging or bulk packaging), as well as non-food products such as paint and other products in the chemical and other industries. How The Neaen Lcc Lid-Closing Conveyor Works Tubs or buckets which the operator has partially covered with…Read More

NEAEN CC Air-Cooling Conveyors

NEAEN CC air-cooling conveyors are designed for intensive cooling of the products after frying, cooking or blanching, using air blown at an ambient temperature. NEAEN CC ambient air-cooling conveyors effectively reduce the product temperature (in most cases in just a few seconds), immediately stopping their cooking. The product is cooled to a temperature suitable for…Read More