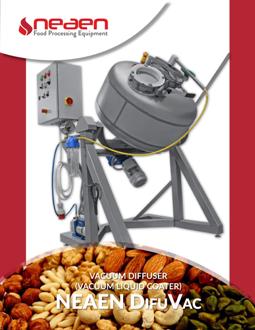

Vacuum diffuser (vacuum liquid coater) NEAEN DifuVac

Vacuum diffusion is a process where the air inside of a product is eliminated with the help of a vacuum. The emptied pores are then filled with flavoring agents, vitamin additives, etc.

The NEAEN DifuVac vacuum diffuser is intended for performing diffusion treatment of a wide range of products, both low- and high-density.

Products:

- Animal food

- Nuts

- Seeds

- Granules

- Grain products

- And more

It is ideal for applying salt and sugar solutions, as well as water-based or oil-based ferments, vitamin and anti-oxidant preparations, as it ensures even distribution of even a small quantity of additives across a large volume of product.

Additives are added during constant mixing, which ensures that it is evenly distributed across the entire volume of the product, even under conditions of vacuum.

Unlike with traditional methods of applying ingredients on the outside of the product, the additive does not remain only on the surface of the product, but it penetrates into the product and reaches its pores, thus significantly increasing the taste and smell of the product.

How it works

The dry product is poured into the chamber. The vacuum is switched on, upon which air is eliminated from the chamber and from the pores of the product. After the air has been eliminated and under constantly mixing, the additive is supplied into the vacuum chamber and is evenly mixed and uniformly distributed across the entire volume of the product.

After the necessary amount of the additive has been introduced and distributed, the vacuum is rapidly relieved. In this way the additive coming from the outer surface of the product is squeezed towards the inside with the help of atmospheric pressure, and it fills the pores which were previously filled with air.

Advantages

Distinctive design features and advantages of the NEAEN DifuVac vacuum diffuser

There is no mixing device. Thanks to the special design, the product is mixed with the aid of a spinning drum, without an agitator as in the case of traditional diffusing machines. This significantly increases the uniformity of mixing and prevents damage to the product, including granules that might be easily ground.

Additives are added while mixing. Uniform distribution of even a small quantity of an additive across the entire volume of the product.

Adjustable vacuum pressure. Allows selecting the right diffusion mode for any product.

Economical to operate. The right dosage of the additive prevents it from being wasted (especially important in the case of expensive vitamins and other similar ingredients) and there is no need for drying the product.

Easy to operate. All necessary processes are carried out within just one plant.

Options. If needed, the NEAEN DifuVac vacuum diffuser can be equipped with a heating system, a loading system with product dosing, an additive injecting system with a collecting tank, or an automatic control system with programmed recipes for various types of products.

Reliable design. The equipment is made in the EU at our own manufacturing facilities, using European materials and parts.